- Nanital, Uttarakhand

Talc is a naturally occurring mineral that is often used in cosmetics because it is soft, smooth, and absorbs moisture. It is used in a variety of products, including:

Baby powder

Body and shower products

Lotions

Feminine hygiene products

Eyeshadow

Foundation

Lipstick

Deodorants

Face masks

Talc powder is used in paints and coatings for a variety of reasons, including:

Talc powder is a naturally occurring mineral that is used in a variety of industries, including pharmaceuticals. In pharmaceuticals, talc is used as an excipient, which is a substance that is added to a drug to improve its performance or make it easier to manufacture.

Talc is used in pharmaceuticals for a variety of reasons, including:

Talc powder is used in ceramics for a variety of reasons, including:

Talc powder is used in rubber for a variety of reasons, including:

Talc powder is used in ink and pigment for a variety of reasons, including:

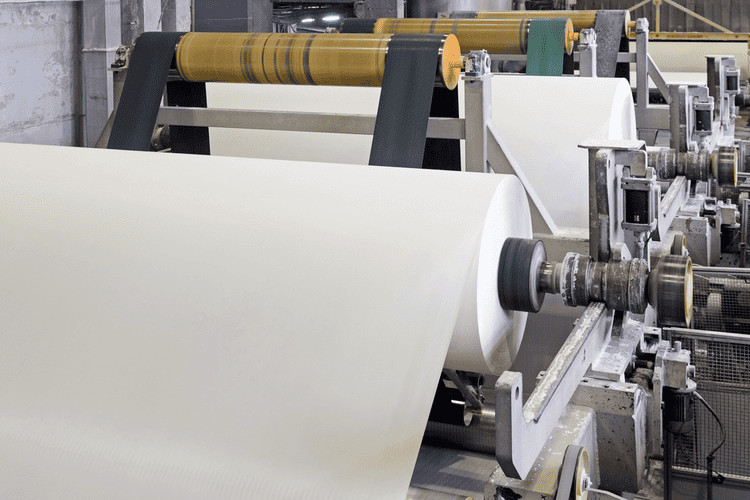

Talc powder is used in paper for a variety of reasons, including: